Don't just sell BIM.

Deliver Intelligence.

You provide the Model & Data. We build the Digital Twin.

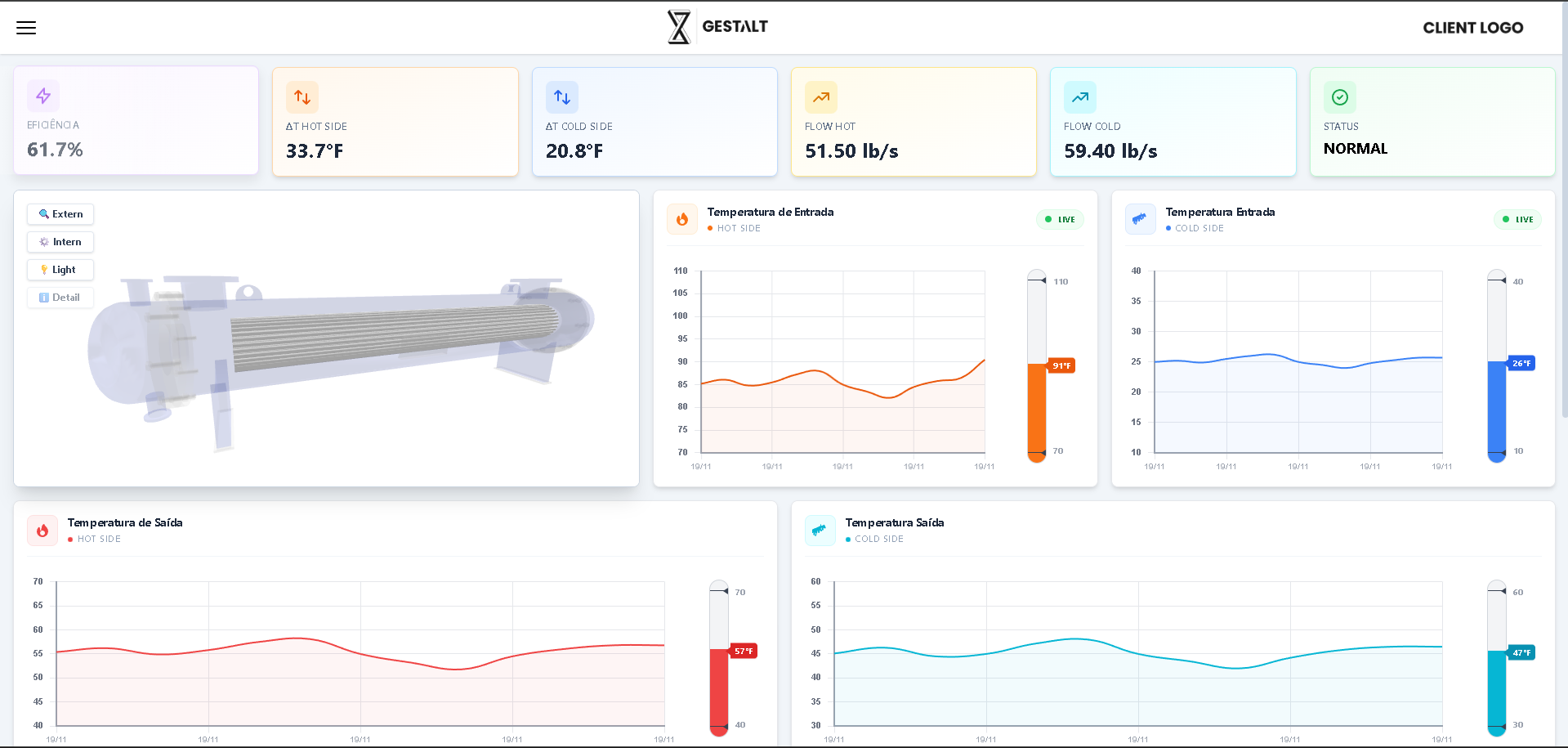

Elevate your BIM services with Gestalt's custom dashboards.

How We Work

A simple workflow to transform your static files into active dashboards.

You Send the Assets

You provide the BIM Model (Revit/IFC) and access to the Data Source (IoT Sensors, Excel, SQL, or API keys).

We Connect Everything

We ingest your model into Autodesk Tandem for governance and wire up the sensor data to the 3D elements using our engine.

You Deliver the Ecosystem

It's not just a dashboard; it's a legacy.

We hand you a Custom 3D Dashboard for daily operations

+

full Autodesk Tandem access for engineering governance.

Stop delivering static files.

Start delivering living assets.

The Foundation

Autodesk Tandem

We use the industry standard to ensure your BIM data is secure, compliant, and structured correctly.

- Single Source of Truth

- Enterprise Security

The Delivery

Superior Dashboard

We build the visual interface your client wants. Whether it's a simple KPI monitor or a complex industrial control panel, we code it.

Custom Visualization

We don't rely on standard viewers. We build lightweight, fast 3D experiences.

Any Sensor, Any Data

If you have the API or database, we can visualize it.